Definition

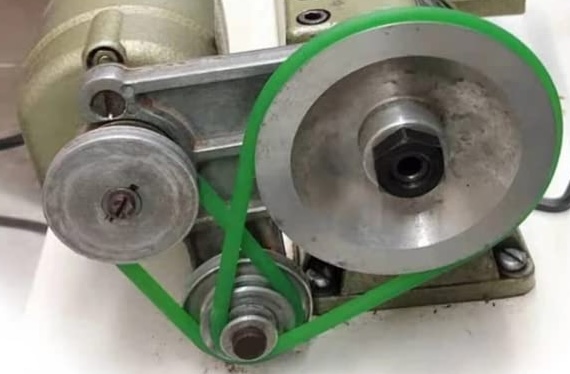

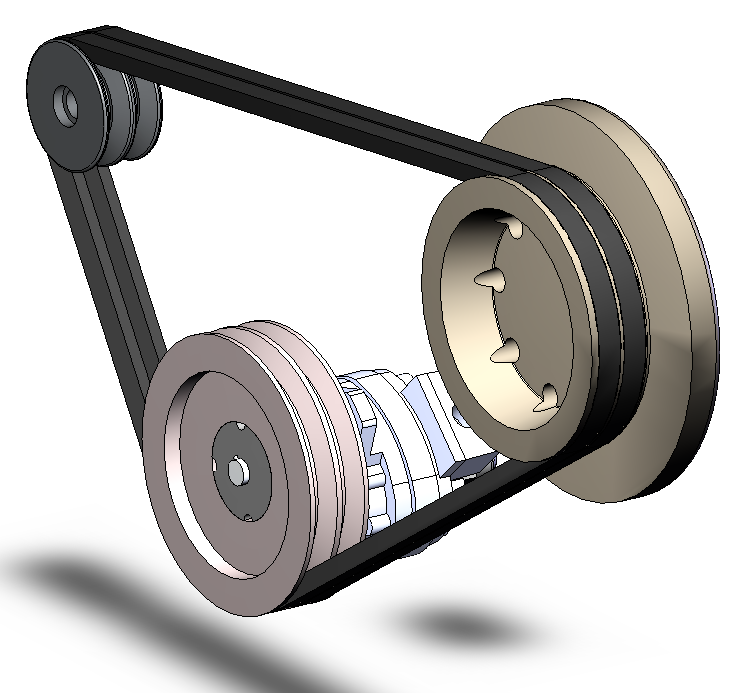

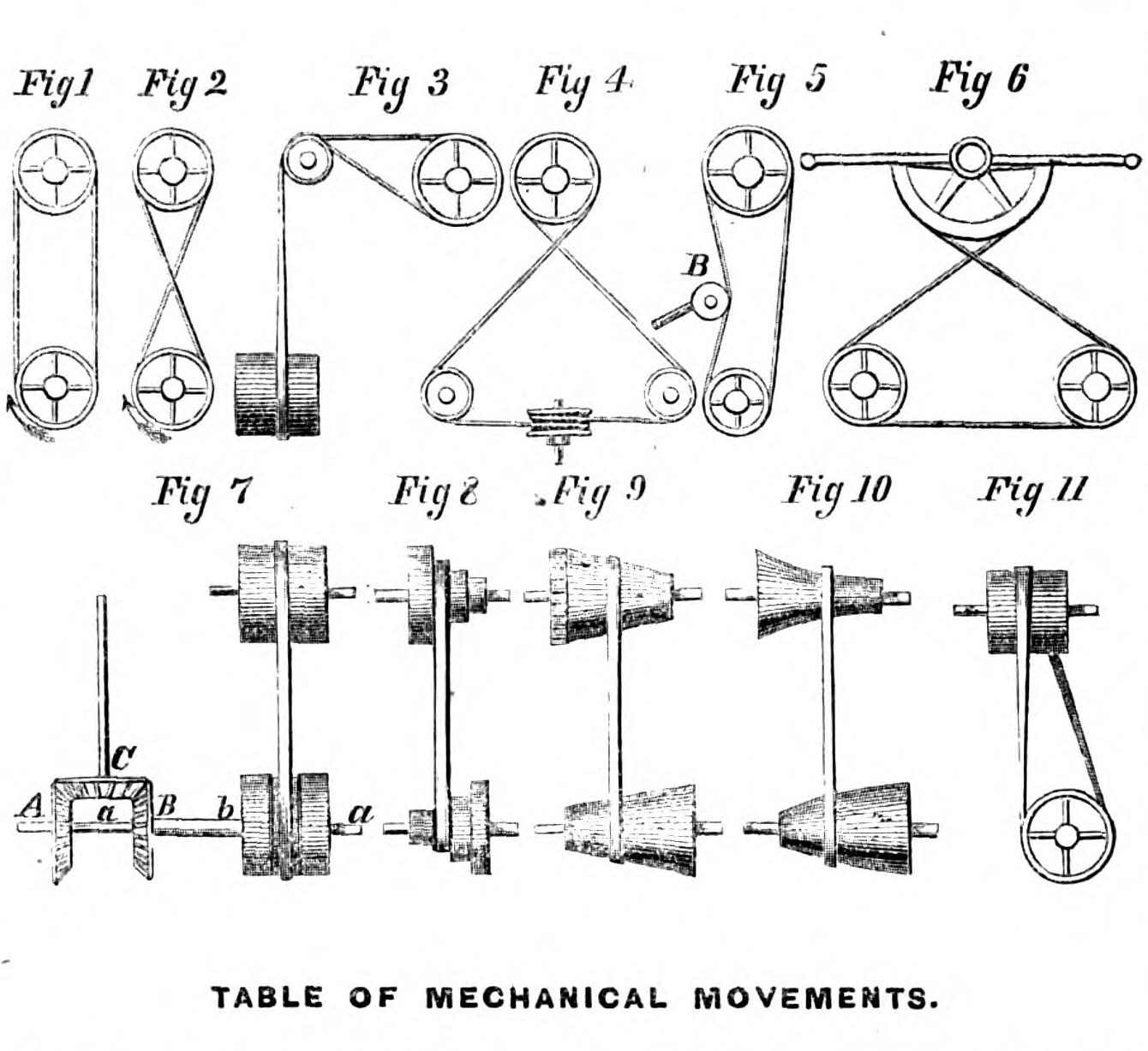

A Belt is a loop of flexible material, often rubber or leather, used to transmit rotational power from one round shaft to another. Belts may have a twist between the pulleys, and the path can be guided around corners.

Belts are very much descended from the belts that hold up pants. For centuries, leather was the strongest flexible material available.

Key Facts

- Toothed Belts are complex cast parts that essentially cannot be fixed by the end user. Because they do not stretch and cannot be unlinked like a chain, so you must design around them. As a practical example, removing the rear tire on a belt-driven bicycle can be complex.

- Belts or chains require tension that is neither too tight (causing stretching) or too loose (reducing power delivery or even skipping teeth). Belt and Chain tensioners or idler wheels are used to take up slack.

- Chains can be shortened or lengthened with a chain tool that pushes the internal pins out. Chains sometimes have a "Master Link" for quick release of a chain.

- Belts versus Chains is a common design question with different answers depending on the specific design. Metal and plastic chains, belts, and toothed belts have different weight, breaking strength, wear, and responsiveness.

- FRC Robotics team 234 Belt vs Chain evaluation and Discussion

- Belt-Driven Bicycles vs traditional chains is a hotly debated topic. Here is one Comparison Cars.com article on timing belts and chains, with a focus on long term wear.

Engineering Rules of Thumb

- Keep in mind the ability to alter the length during design, for example quickly adding or removing links in a chain. Toothed belts are very powerful, but typically must be ordered, causing delays, and come in standard sizes.

- You might consider starting with chain and replacing with a toothed belt when the design becomes stable.

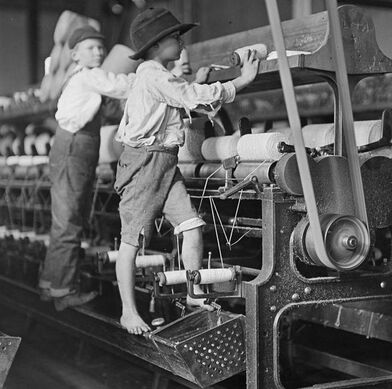

- Chains and toothed belts might always seem like the best solution, but it is often important that a belt should slip! Many machines will happily rip them selves apart in a "jam" if the motor is directly connected to all parts. This is also important when working around human bodies, which must be protected. In some cases, designing a clear weak spot protects the machine by having it break in a predictable, easily fixed, location. For reference, this Home Machinist Lathe discussion.

- Toothed belt efficiency can be the highest, but well maintained chains and V belts can all be quite close. If you are designing an automobile engine, you care about long term wear. If you are making a FRC robot, you probably care about speed to prototype and strength.

- Belts are typically run at a much higher tension to avoid skipping. However, high tension can wear out bearings or bend aluminum frames if not supported.

View in 3D

Display

This model displays 4 samples of Belts and Chains. A rubber tube belt in upper left. A toothed or timing belt in upper right. A chain in lower right. A Link Belt in lower right, on a "Pulley Stack", which allows adjustable gear ratios.

Images

Videos

3D Printing

Mechanism in Legos

Legos have long supported belts and chains in their models.History

Early gears were made from wood with cylindrical pegs for cogs and were often lubricated with grease from animal fat. Gears were used to change the rotational speed from water wheels or wind mills to power pumps or grain mills. The speed of a horse was typically too slow to use, so wooden gears increased the speed.

Reconstructing the Library Display

The Mechanical Library Gear Reduction display is composed of

- Custom Components

- (1) Custom Laser-cut 1/2" plywood panel (400mm x 400mm)

- (9) Custom Laser-cut 3/16" Acrylic Gears

- (20) Custom Laser-cut 1/4" small Acrylic Gears

- (10) Custom Laser-cut 1/4" clear Acrylic Supports

- (1) Custom 3D printed motor mount

Research

- Model: 007 Chain Drives on Cornell University KMODDL (from Clark Collection)

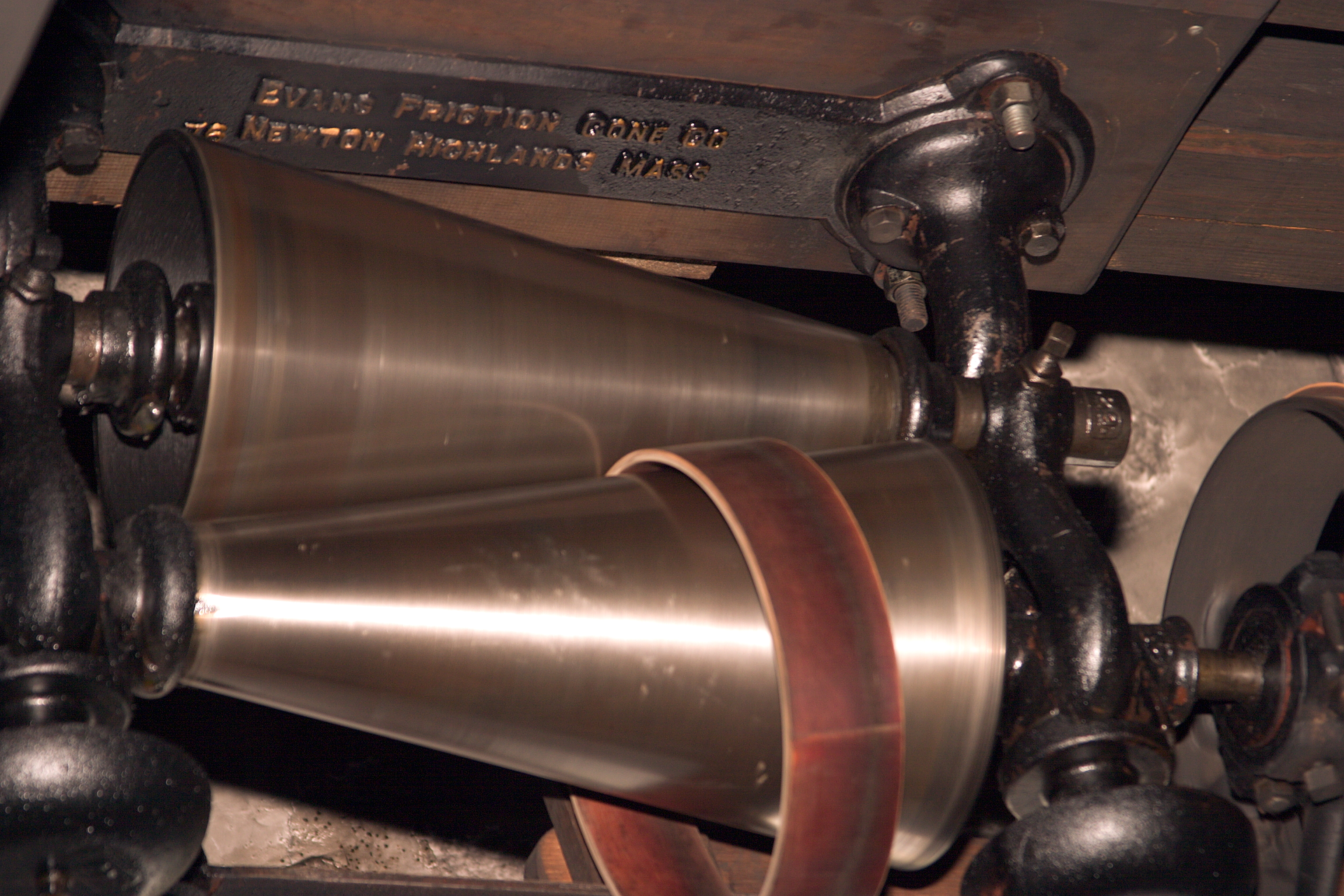

- Model: V02 Belt Drive Between Circular and Conical Cylinders(from Reuleaux Collection, Cornell)

- The Complete Guide to Chain

- Leonardo DaVinci sketch of chain

- Roller Chain

- Mechanical Belt

- Toothed Belt

- Belts vs chains