Definition

Rotary motion was the first motion taken from natural power, river water turning a mill's waterwheel or a donkey walking in a circle around a well. These early machines harnessed the rotational power to a rotational tool like a flour mill. Only in modern time was this rotational power converted into linear motion. This section covers three quite old inventions. In a sense, these are some of the earliest modern machines.

Rotational to Linear mechanisms convert rotating motion into repetitive back-and-forth linear straight-line motion. The three main types are:

Slider Crank: A rotating crank connects to a slider via a connecting rod, creating reciprocating linear motion. Common in engines and compressors.

Scotch Yoke: A pin on a rotating disk moves within a slotted yoke, creating pure sinusoidal motion. Used in valve actuators and some specialized engines.

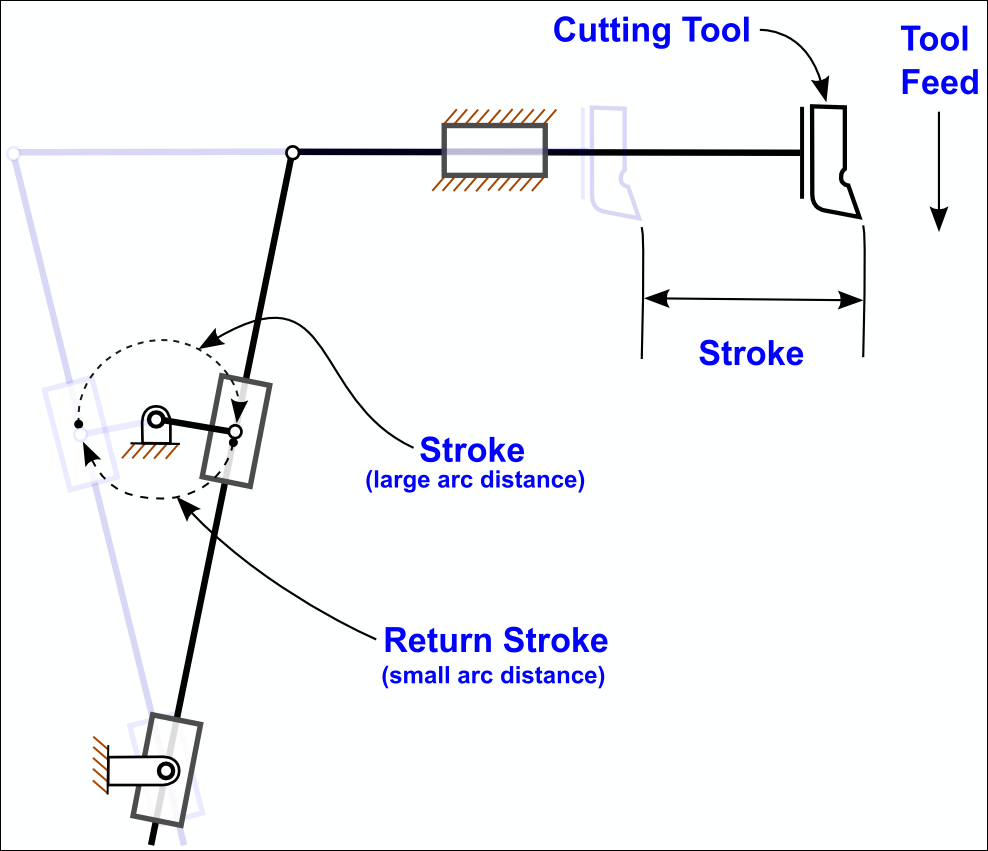

Whitworth Quick Return: An offset crank mechanism where the forward stroke takes longer than the return stroke. Common in machine tools like shapers where work is done only on the forward stroke.

With the exception of the Quick Return, these mechanisms can be run in either direction. The Slider Crank is visible on the outside of a steam train engine. A gasoline engine piston crankshaft has a similar Slider Crank.

Key Facts

- Slider Cranks have higher mechanical efficiency but more parts and friction points.

- Scotch Yokes provide true sinusoidal motion but experience high sliding friction. These mechanisms are less used in modern times as the yoke tends to wear out due to friction.

- Side forces must be managed in all designs to prevent binding and wear.

- The stroke length is determined by the crank radius and offset distance.

View in 3D

Display

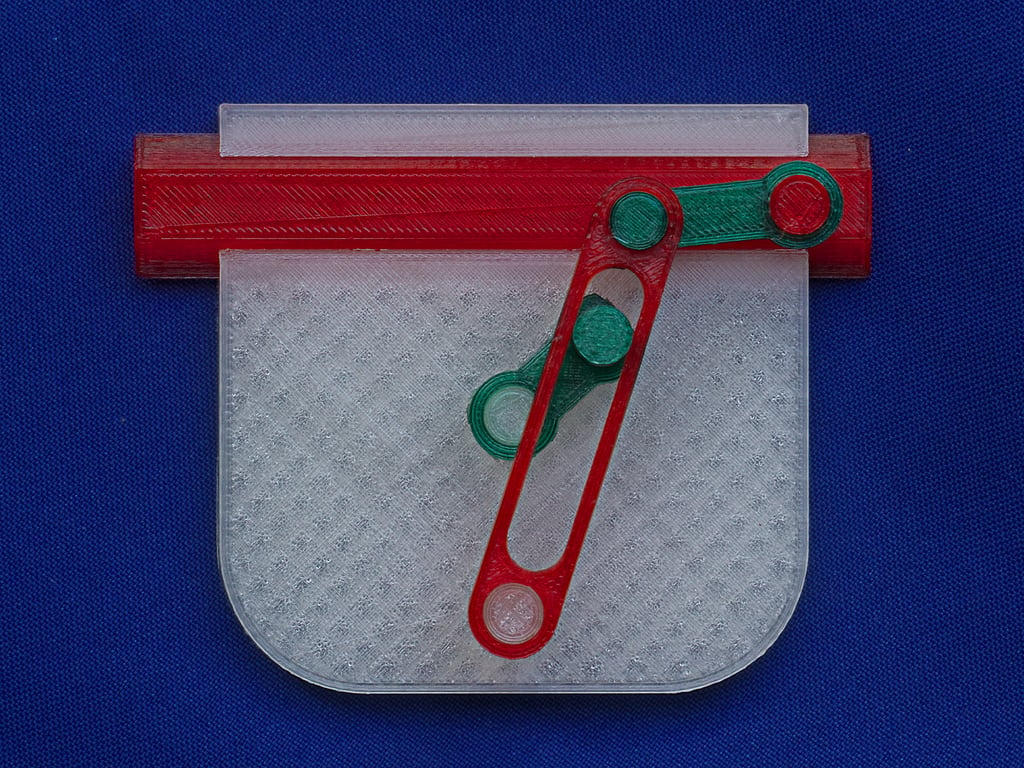

This model demonstrates three rotational-to-linear conversions:

- Top: Classic slider-crank with visible connecting rod

- Middle: Scotch yoke showing pin and slot interaction

- Bottom: Quick return mechanism demonstrating asymmetric motion

The display runs at approximately 100 RPM.

Images

Videos

Scotch Yoke Mechanism

Slider Crank Mechanism

Whitworth Slider Crank Mechanism

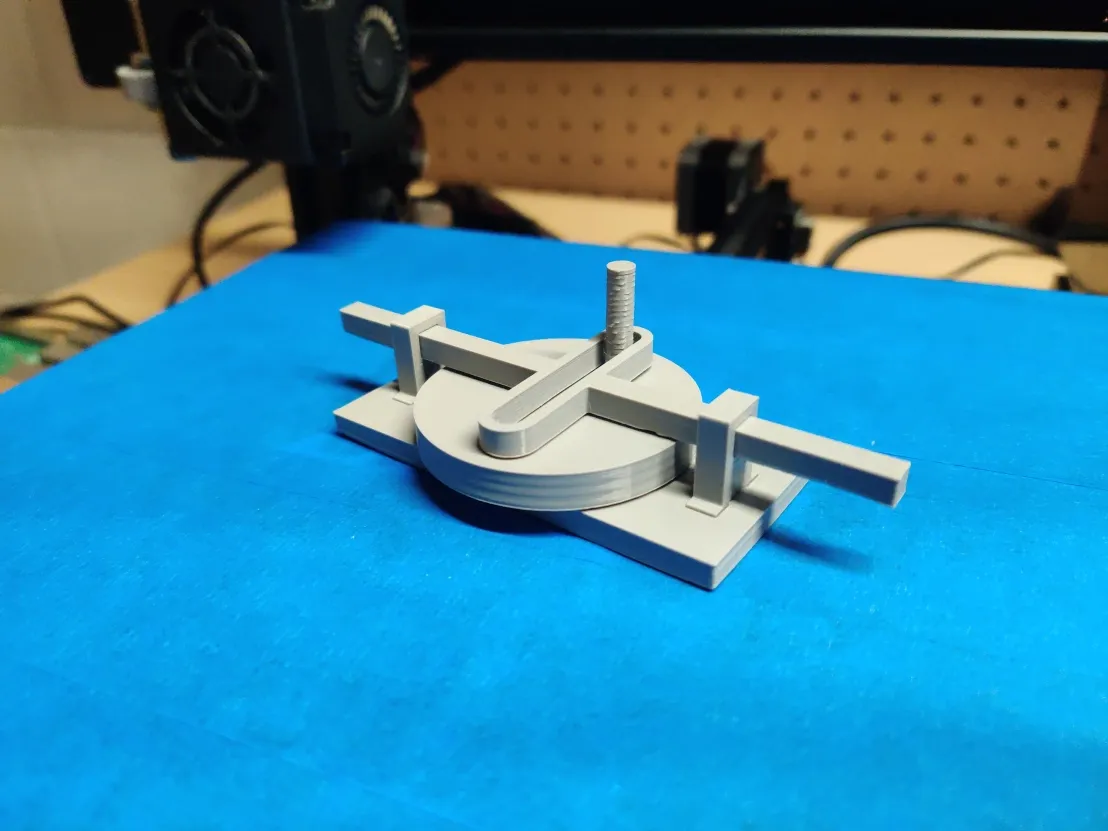

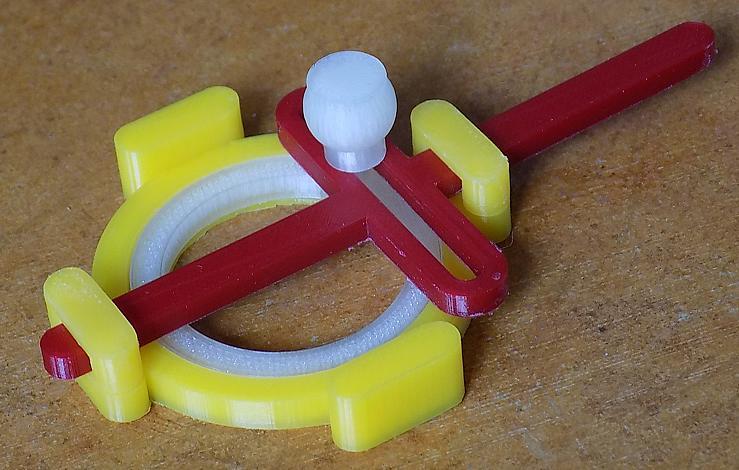

3D Printing

:format(webp)/https://fbi.cults3d.com/uploaders/20586650/illustration-file/b265593d-e611-4cab-a961-7e2f48ac065f/Scotch-Yoke-Exploded-Icon-Copy.jpg)

:format(webp)/https://fbi.cults3d.com/uploaders/14117166/illustration-file/4e326112-74fb-49df-9c3d-f0f355e67ad4/269701736_643067490347366_5492105095996462969_n.jpg)

:format(webp)/https://fbi.cults3d.com/uploaders/13949767/illustration-file/9d6c5ffe-adc2-4121-b2c5-b3e897a0b281/IMG_1556.JPG)

Mechanism in Legos

History

The conversion of rotary to linear motion was crucial to the Industrial Revolution. Early steam engines used beam engines before the development of the slider-crank. The Scotch yoke emerged in the 19th century for applications requiring smoother motion. Quick return mechanisms were developed for machine tools to improve efficiency.

James Watt's parallel motion mechanism (1784) was an early attempt at converting rotary to linear motion while maintaining a straight line path.

Reconstructing the Library Display

The Mechanical Library Gear Reduction display is composed of

- Custom Components

- (1) Custom Laser-cut 1/2" plywood panel (400mm x 400mm)

- (3) Custom Laser-cut 1/4" Acrylic wheels (2 layers, glued)

- (1) Custom Laser-cut 1/4" Acrylic Scotch yoke form

- (1) Custom Laser-cut 1/4" Acrylic Scotch yoke form

- (1) Custom Laser-cut 1/4" Acrylic Slider Crank form (2 pieces)

- (1) Custom Laser-cut 1/4" Acrylic Quick Return mechanism form (3 pieces)

- (3) Custom Laser-cut 1/4" clear Acrylic Supports

- (1) Custom 3D printed motor support to gobilda frame

- (1) 12v 30 RPM DC gear motor with 6mm D shaft output

- (1) 12v Power supply

- (1) 6mm D shaft coupler

- (7) Flanged Ball Bearing (6mm)

- (3) 1121 Series Low-Side U-Channel (10 Hole, 264mm Length)

- (2) 1121 Series Low-Side U-Channel (3 Hole, 96mm Length)

- (1) 1121 Series Low-Side U-Channel (13 Hole, 336mm Length)

- (3) 1201 Series Quad Block Pattern Mount (43-2)

- (3) 1309 Series Sonic Hub (6mm Bore)

- (3) 6mm D-Shaft (Stainless Steel, 100mm Length)

- (3) 2920 Series Steel Set-Screw Collar (6mm Bore) - 2 Pack

- (3) 3307 Series 8mm Pitch Steel Set-Screw Sprocket (6mm D-Bore, 10 Tooth)

- (3) 8mm Pitch Plastic Chain

- Various M4 screws

Research

- Model: 007 Chain Drives on Cornell University KMODDL (from Clark Collection)

- Model: V02 Belt Drive Between Circular and Conical Cylinders(from Reuleaux Collection, Cornell)

- The Complete Guide to Chain

- Leonardo DaVinci sketch of chain

- Roller Chain

- Mechanical Belt

- Toothed Belt

- Belts vs chains

- Scotch yoke

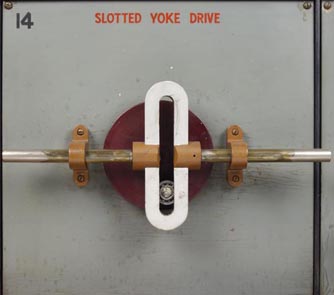

- Scotch Yoke -Clark model # 14 (from Clark Collection in Cornell University KMODDL)

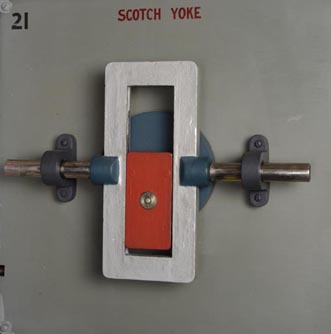

- Scotch Yoke -Clark model # 21 (from Clark Collection in Cornell University KMODDL)

- Slider-crank linkage

- Oscillating Cylinder Engine -Clark model # 147 (from Clark Collection in Cornell University KMODDL)

- Quick return mechanism

- History of Sir Joseph Whitworth

- Excellent collection of Slider Crank videos

- Slider Crank section of Kinematics of Machines by Durley, Richard John (1907)

- CRANK AND SLIDER MECHANISM on https://technologystudent.com

- QUICK RETURN CRANK MECHANISM on https://technologystudent.com